CSED - Smart Manufacturing Programme

Appreciation inspires us to give the best quality education

CSED - Smart Manufacturing Programme

I take this opportunity to extend to you a warm welcome to the IIMT Group of Colleges, Greater Noida.

SMART MANUFACTURING

| DEPARTMENT | PROGRAM |

|---|---|

| Product Design Department | Product Design |

| Manufacturing Department | Product Manufacturing |

| Advance Manufacturing Department | Smart Manufacturing |

| Mold Design & Manufacturing Department | Injection Mold Design & Manufacturing |

| Analysis Department | Product Analysis |

| Press Tool Design & Development Department | Press Tool Design & Manufacturing |

1. PRODUCT DESIGN

| SCOPE |

|---|

| Design Engineer |

| Product Development Engineer |

| Entrepreneur |

| PROJECTS |

|---|

| New Product Development |

| Excavator Design |

| Designing of Automobile Parts & Assemblies |

OBJECTIVES

- To learn the Sketcher Workbench.

- To learn Part Modelling and Designing.

- To learn Wireframe and Surface Designing.

- To learn Assembly Designing.

- To learn Drafting Workbench.

- To learn Product Development Process.

OUTCOMES

- To give shape to the idea, concept design, and controlling the geometrical shape of the designed component.

- To create 3D model of the designed concept, understanding the part designing requirements that fulfil the design needs of various modules like CAM, CAE, Tool Designing, Drafting, 3D printing.

- To understand, create, control the complex shape geometries.

- To design & develop a new product from the existing one.

- To design assemblies, mechanism for validation.

- To understand the industrial drafting standards and generating industrial drawings.

2. PRODUCT MANUFACTURING

| SCOPE |

|---|

| Production Engineer |

| CAM Engineer |

| CNC Supervisor |

| Entrepreneur |

| PROJECTS |

|---|

| Manufacturing of machine tools |

| Manufacturing of automobile parts |

OBJECTIVES

- To learn different manufacturing process.

- To learn Computer Aided Manufacturing (CAM).

- To learn integrated design and manufacturing.

- To learn CNC programming and machining.

- Manufacturing process optimization.

- To learn jigs and fixtures design.

- To learn Computer Aided Manufacturing using 4 Axis machining centre.

OUTCOMES

- To give shape to the idea, concept design and controlling the geometrical shape of the designed component for manufacturing.

- Geometric and Dimensional Tolerance.

- Understanding process planning.

3. SMART MANUFACTURING

| SCOPE |

|---|

| IIOT Designer |

| IIOT Developer |

| IIOT Analyst |

| IIOT Tester |

| PROJECTS |

|---|

| Converting existing machine into smart machine |

| Machine maintenance analysis |

| Development of Smart Machinery |

| AI for maintenance and overhauling |

OBJECTIVES

- To learn the concepts of IIOT.

- To learn the concept of Industry 4.0

- To identify different technology.

- To learn different applications in IIOT

- To learn different protocols used in IIOT.

- To learn the concepts of smart manufacturing development in IIOT.

- To learn the use of IIOT for Predictive Maintenance and Production Control.

OUTCOMES

- Apply the concepts of IOT.

- Identify the different technology.

- Apply IOT to different applications using Thingworx.

- Analysis and evaluate protocols used in IOT.

- Design and develop smart machines in IOT using Thingworx.

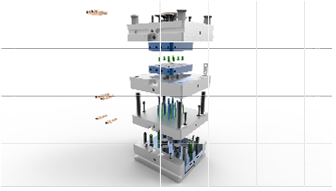

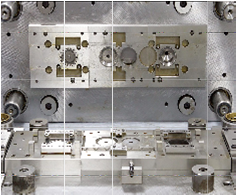

4. MOLD DESIGN AND MANUFACTURING

| SCOPE |

|---|

| Mold Design Engineer |

| Plastic Mold Designer |

| CNC Program Engineer |

| Entrepreneur |

| PROJECTS |

|---|

| Design & manufacturing of molds for plastic components. |

| Design of injection mold. |

| Manufacturing of injection molds for different industries. |

OBJECTIVES

- To learn the plastic part design requirements.

- To learn the procedure of mold design and its various parameters.

- To validate the design of mold design setup, analysing part design for best gate location and analysis of mold flow.

- To learn the mechanism design procedure and connection between the components.

OUTCOMES

- This enables the students to demonstrate mold making process as well as to work on different types of molds.

- Will be capable to design various injection molding set up components like core, cavity etc.

- Understanding & interpreting results and molding parameters, and also troubleshooting molding problems.

- To analyze scanned data for checking interference between the components etc.

- This enables to configure the motion, evaluate the analysis results.

- It enables to understand various machining processes and creating NC sequences for milling.

5. PRODUCT ANALYSIS

| SCOPE |

|---|

| Product Analyst-Engineer |

| Product Development Engineer |

| Product Manager |

| PROJECTS |

|---|

| Reverse engineering on disk brakes using thermal analysis. |

| Product analysis of automobile parts. |

| Static structural analysis of plastic parts made from 3D printer. |

OBJECTIVES

- To learn simulation of product design and conduct different kinds of analysis.

- To understand pre processing.

- To understand convergence.

- To understand post processing.

OUTCOMES

- Ensures that the product is ready to manufacture and achieves the desired results.

- Ensure the product does, what the company claims it does by sustaining in practical application.

- Provide alternative designs options and study cost effective while meeting the customer requirements.

- The results can aid the business in manufacturing, QA, logistics, and sales.

6. PRESS TOOL DESIGN & MANUFACTURING

| SCOPE |

|---|

| Sheet Metal Designer |

| Tool and Die Designer |

| Entrepreneurship |

| PROJECTS |

|---|

| Design of sheet metal component for machine design & electronics industry. |

| Tool design for sheet metal component. |

| Manufacturing of press tool. |

OBJECTIVES

- To learn sheet metal model fundamentals, creating primary and secondary sheet metal wall features.

- To learn bending and unbending sheet metal models, form features and modifying sheet metal models.

- To learn the process of sheet metal setup and tools and detail sheet metal designs.

- Design of blanking, piercing, progressive and compound dies.

- Introduction & guidelines for design of press tools.

OUTCOMES

- Demonstrate various press machine operations for mass production of sheet metal parts.

- This enables to understand the mechanism behind the effective designing and modifying of the models.

- Prepare working drawings and setup for economic production of sheet metal components.

- Illustrate the principles and blank development in bent & drawn components.

- Identify press tool requirements to build concepts pertaining to design of press tools.